CONVENTIONAL Terminations

Even with ‘Audiophile’ cables, terminations are often an afterthought. Terminations that utilize screw pressure to clamp against the side of a conductor result in minimal actual contact area between the sides of a few conductor strands. Screws are designed to fasten, not to create a secure, low-resistance, reliable contact. These terminations invite contamination of the contact surfaces and degrade over time as the cable and screw housings age.

Soldered connections are an improvement over mechanical connections but are inherently inconsistent and subject to fatigue and cracking over time. Solder also tends to wick up conductor strands, stressing the conductor where the solder ends. Most litz cable is terminated using solder as this is the easiest method to deal with the individual strand insulation.

Zero Loss Connectivity

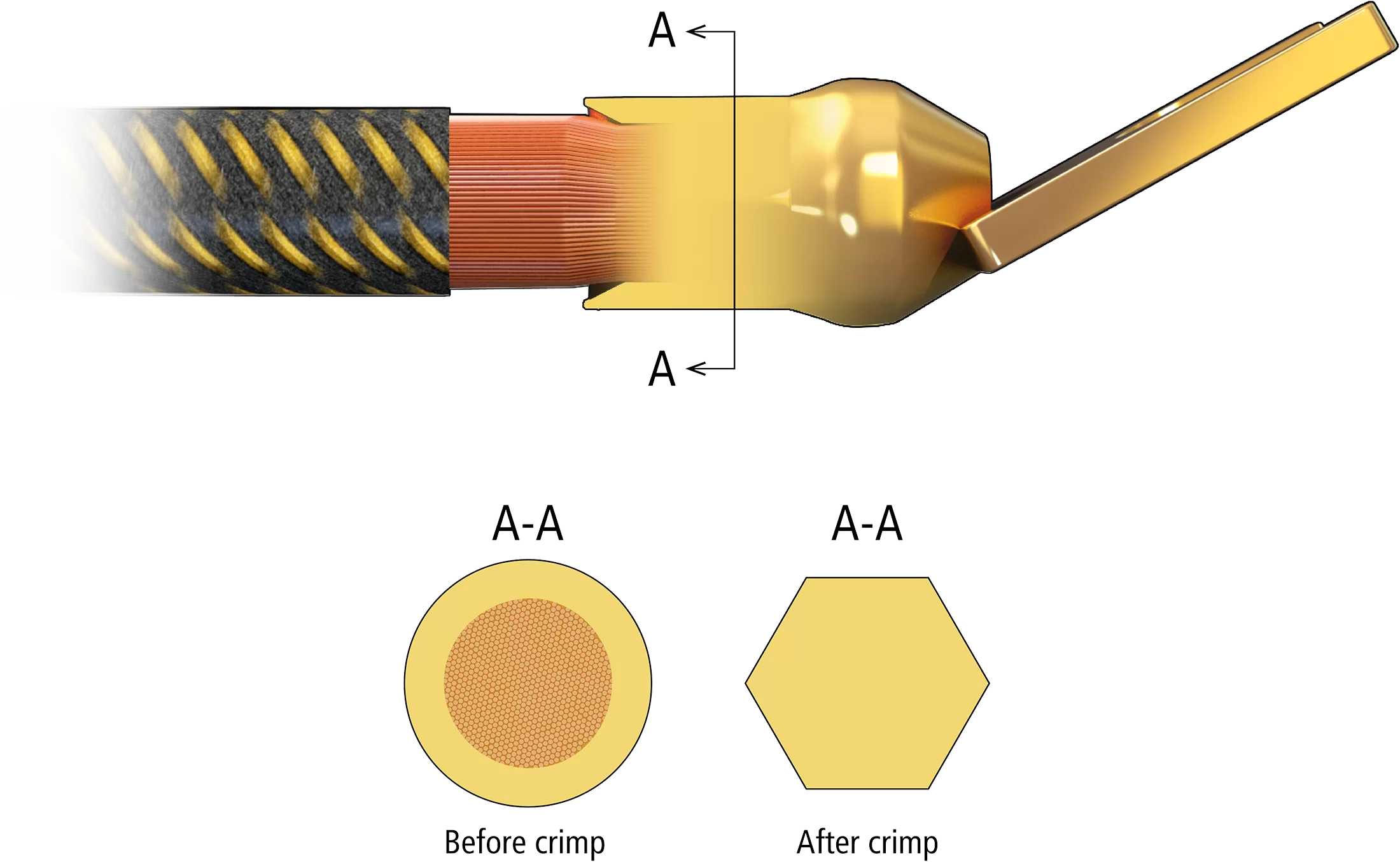

A cold weld, metal-to-metal fusion so complete, contact resistance is eliminated and with no degradation over time.

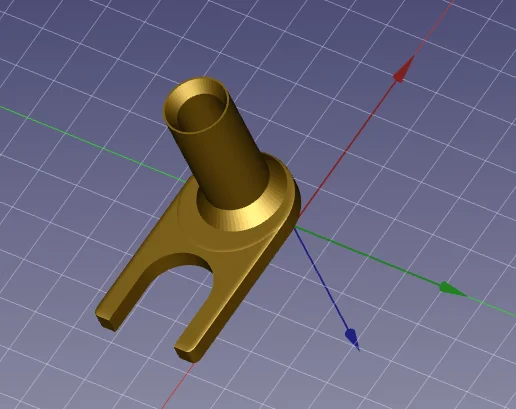

The best possible termination is a uniformly crimped, cold weld termination. VANISH cables are terminated by first removing the litz insulation via a unique methodology, and then immediately crimping over the remaining pure copper strands and environmentally sealing the assembly to prevent any opportunities for oxidation. Our crimping process utilizes a 13 ton hydraulic press and applies force equally around the diameter of the cable, creating a uniform, durable, consistent cold weld connection with zero contact resistance.

Gold Plating

Experience NASA-Grade Perfection in Every Connection

When NASA needed flawless performance for the Hubble and James Webb space telescopes, they chose Epner Technology’s exclusive Laser Gold process. Now, that same technology is used to plate Vanish loudspeaker terminals. This plating is both 99.99% pure gold AND with a knoop scale hardness of nearly 200 – compare these specs to terminals used on any other cables at any price. While other manufacturers settle for inferior terminals, we deliver the same process that ensures billion-dollar space missions never fail.

Custom Terminations

Please see the cable configuration pages for our standard 30 degree and 90 degree spade terminal dimensions. If our standard offerings do not meet your needs, SMR Cable Technologies offers a complete custom cable termination solution for your system.

How it works:

You provide pictures, measurements, and any other information that will assist in designing a custom terminal that meets your equipment requirements. We will contact you if we require additional information or need to discuss your terminal requirements. We may also contact your equipment suppliers directly if required.

We will design and 3D print a custom, dimensionally accurate representation of a terminal that is compatible with our cable and termination process, and send this to you to confirm that it is compatible with your speakers and amplifier.

Upon approval of the custom terminal, we will proceed to manufacturing.

Each custom terminal package is quoted individually, but the typical custom terminal cost adder for a set of cables (8 gold plated, copper terminals) is approximately $1800 and takes between 30 and 45 days.